Custom design

Custom design

Characteristics

The Custom Design Series are in Monoblock or in 3 pieces, but produced according to the customer's design, which helps to make the car more attractive and original.

Providing a drawing, sketch, or photograph of the required design is enough for our engineers to prepare a full-fledged 3D model and manufacture the wheels.

Availability

Made of high-quality aluminium, these wheels are available from 17" to 23" in diameter. In addition to technical parameters like PCD, ET, centre hub, and the correct inner profile for the brakes, the mass of the car is considered to calculate the load.

We also offer a variety of different finishes and centre cap options.

We introduce an order process as clearly and simple as possible.

The process is as follow:

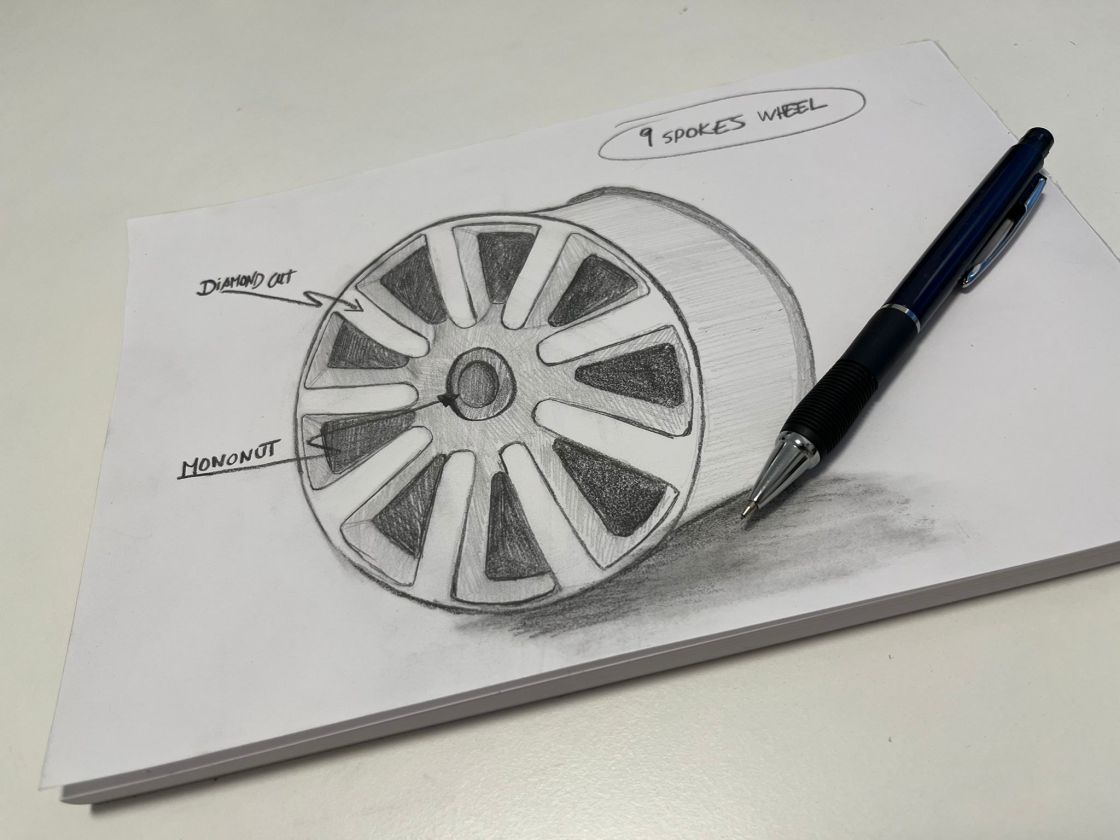

Step 1 - Sketch

The client sends us a drawing, diagram or image/photo that supports his explanations. Drawing can even be done by hand, as long as it shows the idea.

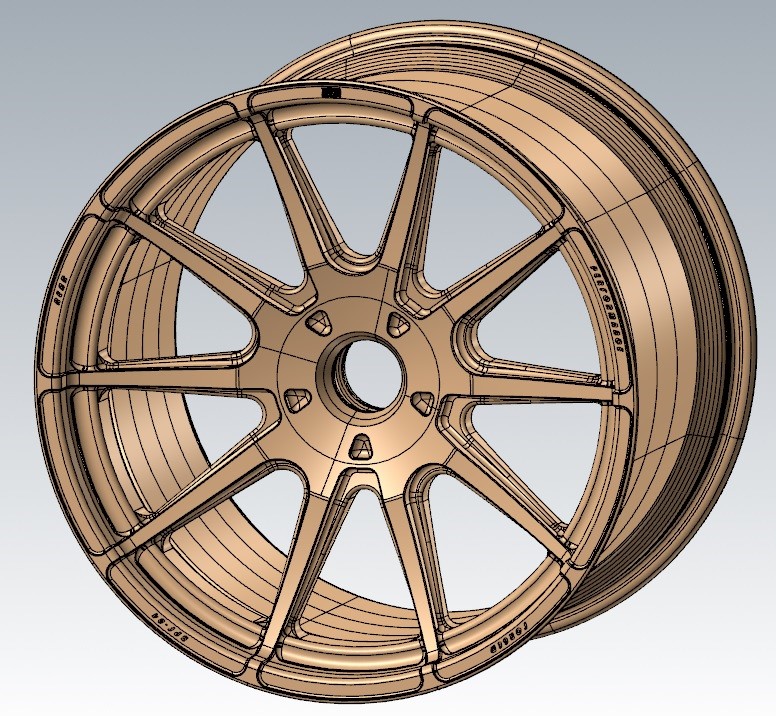

Step 2 - 3D Model

According to the information received, a 3D model is prepared and submitted for the client to check and improve, if necessary, his dream.

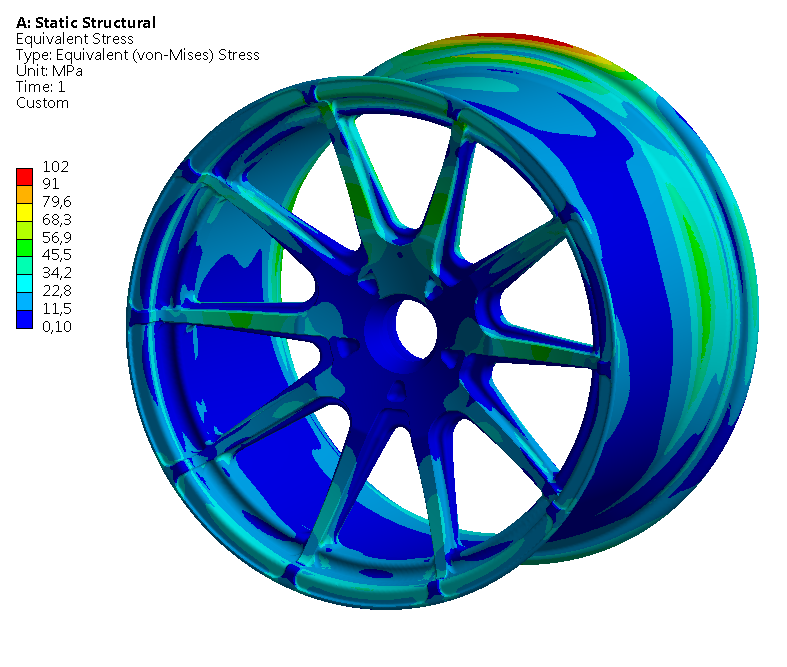

Step 3 - FEA

Adjustments are made to the design according to customer's wishes and comments, calculations of loads and resistance are finished, and the final design to be send to production is approved.

Step 4 - Manufacturing

Machining and milling begins. The wheels are manufactured according to the approved 3D model. This stage can take between 2 to 4 weeks depending on the complexity of the design

Step 5 - Finishing

Once the wheels are milled, the finishing and painting process begins, which will be carried out according to the client's requirements.

Step 6 - Inspection & Shipping

After completing the final inspections checking, the wheels are boxed and shipped to the customer.

Step 7 - Assembly

The customer receives the wheels and mounts them on the car.

It is proven that dreams sometimes come true

Send your sketch

Responsible: Tecnología y Fabricación, S.A.

Purpose: To manage the sending of information related to the petition. +info

Legitimation: Consent of the interested person +info

Recipients: Tecnología y Fabricación, S.A.

Additional information: Privacy Policy